PILLOW – PRE-WEIGHING AND FILLING

Alan Pillow S

The ALAN PILLOW S is a family of filling machines made with one or two workstations. They are designed to satisfy customers who need medium-small batch production. Each model hold up to two weighing modules with automatic control for maximum performance.

ALAN PILLOW S is not a machine, it is a platform with modules that can be integrated, capable of creating a family of machines that perform well because optimized. The main structure hosting the main silo, is equipped with a material suction system, a filter to contain the loaded material and pipes for unloading and maintenance. An ALAN PILLOW S machine can be equipped with one or two injection modules, with adjustable high pressure fans, leaving the operator in control of the filling of the product. The second work station, if present, will work independently from the first. Machine can be provided with up to two pre-weighing modules and an injection management control, facilitating the operator’s work and improving product quality. The injectors, available in various sizes, are equipped with a quick change over. The ALAN PILLOW S range has been designed to satisfy customers who need medium-small batch production.

Alan Pillow 2/3

ALAN PILLOW 2/3 are machines designed to fill cushions with feathers, synthetic fibers and recycled materials. Compared to traditional filling systems, this machine has greater precision in the quantities programmed for each individual filling and a greater speed of execution of the fillings. Over the years, ALAN PILLOW 2/3 has become the reference point in the production of medium quantities of sofa cushions, of pillows and furniture cushions. Many versions are available.

The machine ALAN PILLOW 2/3 consists of a storage module, a weighing module consisting of two or three scales, a control panel for programming, an injection module and a tank for loading the storage box. Compared to traditional filling systems, this machine has greater precision in the quantities programmed for each individual filling and a greater speed of execution of the fillings. The ALAN PILLOW 2/3 can be equipped with a table for positioning the products to be filled in front of the injector which allows the recovery of the feathers escaped during the filling process of the pillow. Over the years, ALAN PILLOW 2/3 has become the reference point in the production of medium quantities of sofa cushions, of pillows and furniture cushions. Different configurations are also available with push injection units for innovative applications.

Alan Pillow A

ALAN PILLOW A is a family of machines designed with a modular approach, to meet all production needs in the pillow sector, cushions within the furniture sector, where high production capacities are required. ALAN PILLOW A can be configured with several pre-weighing modules (from 3 to 10) depending on the hourly production required. The same approach with the injection units allows the machine to fill in a short time and the transfer to the closing system can be both manual and fully automatic, through an anthropomorphic robot or through special applications. ALAN PILLOW A minimizes the use of personnel and reduces the waste of raw materials. The system can treat all types of filling material, from feathers / down, to various types of synthetic fibers, from the most varied recycled and composite materials.

ALAN PILLOW is the backbone of the pillow production line. Customers can achieve top performance thanks to the complete integration of ALAN PILLOW A with other Borsoi machines. Assembled in a single control line according to the “From Bale to Box” philosophy, these machines require few operators and consistently provide high performance.

ALAN PILLOW A is a 100% modular solution to be tailored on customer needs.

Pillow shell forming

Pillow shell forming machine is a machine who assemble the shell of pillow from roller of textile by sewing it’s components. A frame with motorized axis overlap two layer of textile and sews them together. Label insertion is available. Sews are performed from Lockstitch or overlock machine. Pillow shell forming machine is tailor made, no one is equal to another but each one is a masterpiece of mechanical and automatic solutions.

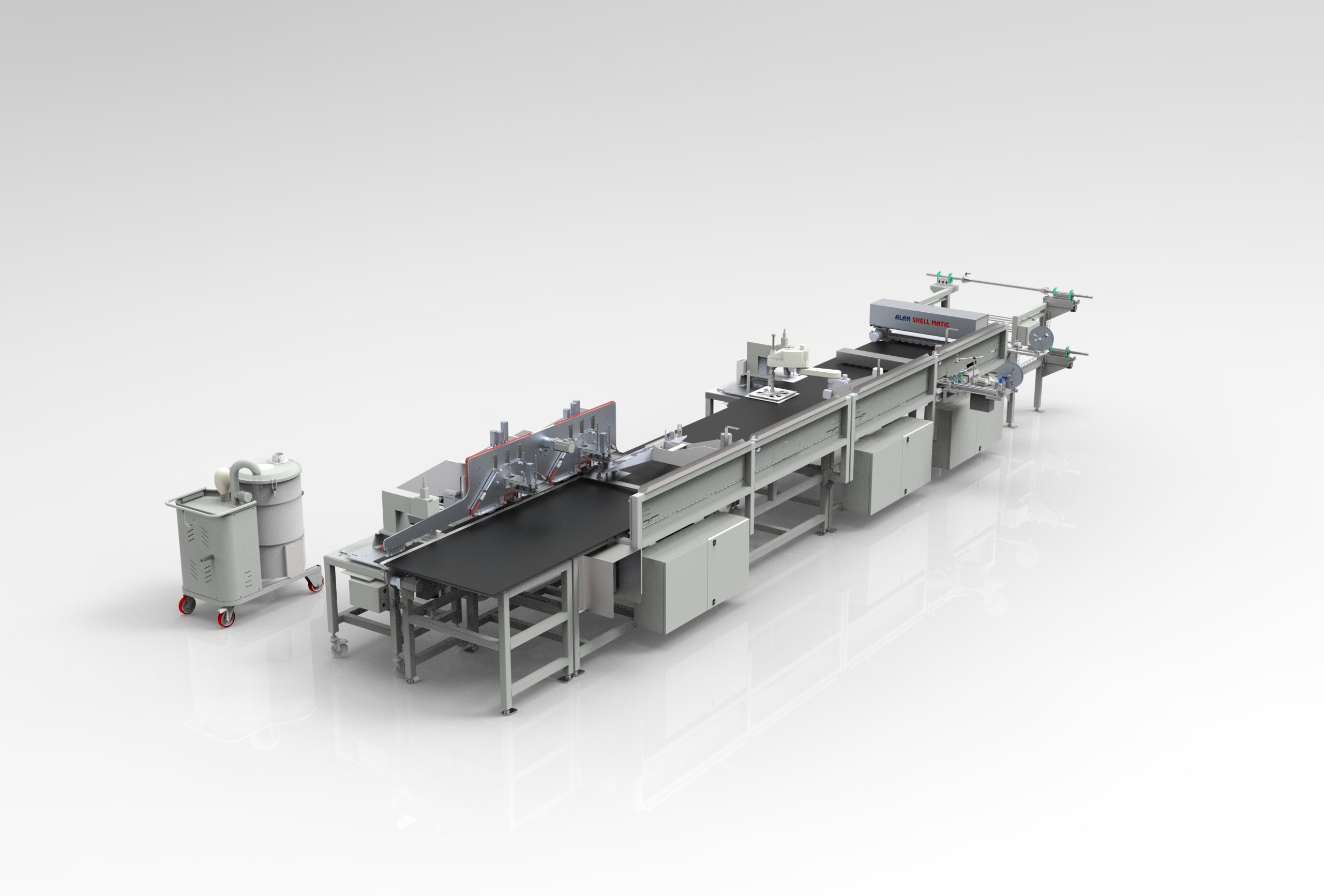

INTEGRATED PILLOW FORMING WITH DUO SYSTEM

In automation, the best performance is achieved by automatically combining and integrating two or more sequential processes. This happens when the pillow shell forming machine is combined with a pre-weighing and filling system, plus a pillow closing system. Made on a single work table, the ALAN SHELL MATIC is combined with a DUO filling system and a cushion closing system, all in a whole assembled solution. Shell shaping and cushion closing can be done via ultrasonic closures or stitching.

Pillow shell unfolding and loading

Pillow shell unfolding and loading systems is an automatic working station full automatic who pick up pillow covers and load them to filling machine. Such solution eliminate the needs of operator at loading station of filling machine. One arm elbow robot is used to pick and place the cover of pillow to the injectors of filling machine, a special hand with clip and sensors is connected to the arm of robot to ensure the task. The operation is repeated until whole production is complete.

Filled pillow unloading

Filled pillow unloading systems is an automatic working station who remove the filled pillow from the injector of filling machine and set it to the closing station, according the phases of filling-closing process of filled pillow production. One arm elbow robot is used to pick and place the filled pillow from injectors of filling machine to the sewing station. A special hand with clip and sensors is connected to the arm of robot to ensure the task.

Pillow shell automatic warehousing

Pillow shell automatic warehouse is the best option to manage and organize stocks of covers. Integrated with software ERP of the company and with control of Borsoi production line, it optimize the production process despite the high number of different models and sizes of pillow customer has to produce. With automatic warehouse is possible reduce the number of each lot and obtain the multi-mix production which optimize the order‘s trend. Lean production oriented, it is the optimum for production with extreme variety of products or with “pull production” strategy.

Copyright 2022 Borsoi Srl - P.iva 04694270267