Quilts – Pre-weighing and filling

Alan PB

ALAN PB is the point of arrival of automatic pre weighing filling machine with weighing. Thanks to its unique double chamber weighing boxes, the ALAN PB machine is a super flexible solution for producing quilts and pillows on the same platform. The ALAN PB is equipped with a powerful air injection unit that can process many types of filling materials such as feathers, down, fiber ball and PS fiber. The machine is considered the “Swiss Army Knife” for the production of bedroom products due to its incredible flexibility. It is the right solution for a small / medium production requirement when the processing of quilts, toppers and pillows is required, using padding of different materials.

Alan Bedding 4

ALAN BEDDING 4 is a 4-scale quilt filling automatic machine with an air injection system for the forced and dosed filling material into beddings. The injection system consisting of two parallel tubes that enable the simultaneous performance of two filling operations. The machine has a material flow weighting unit that allows a greater precision when dosing the filling material during the weighting process. The system consists of 4 scales which make it possible to reach a high hourly production rate in terms of the quantity of filling operations carried out. Originally, ALAN BEDDING 4 was a machine that has been specifically designed to carry out filling operations into quilts, nowadays with new software and with dedicated injection probe it’s also possible to fill pillows.

ALAN BEDDING 4 is a 4-scale quilt filling automatic machine with an air injection system for the forced and dosed filling material into beddings. The injection system consisting of two parallel tubes that enable the simultaneous performance of two filling operations. The machine has a material flow weighting unit that allows a greater precision when dosing the filling material during the weighting process. It consists of double chamber silo, agitators unit, proportional trap doors and 4 scales which make it possible to reach a high hourly production rate in terms of the quantity of filling operations carried out. Filling machine can process many types of filling materials such as feathers, down, fiber ball and PS fiber. Originally, ALAN BEDDING 4 was a machine that has been specifically designed to carry out filling operations into quilts and toppers for medium production range, nowadays with new software and it is possible to fill also pillows using dedicated injector or for special application.

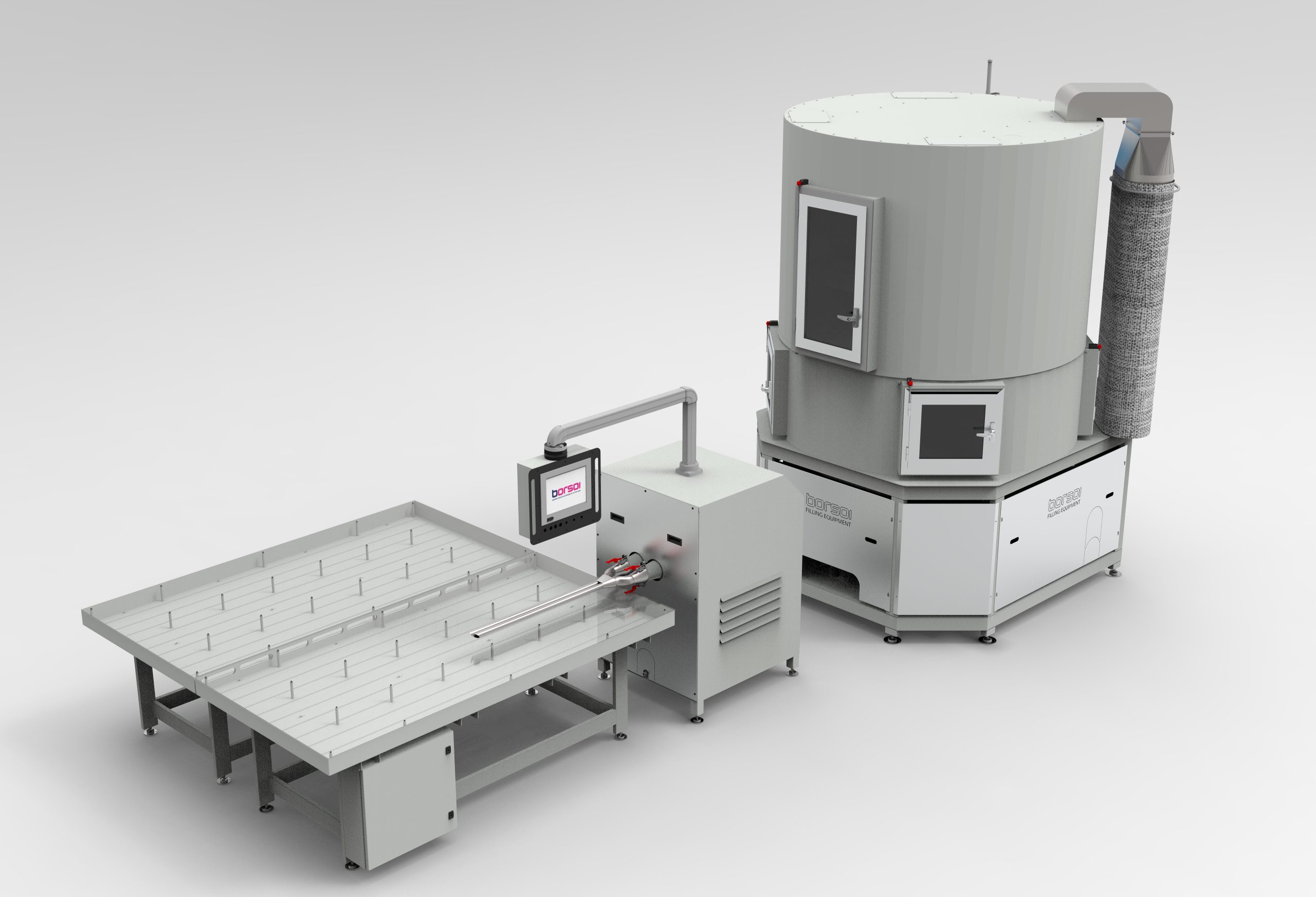

Alan Bedding A

ALAN BEDDING A is a family of machines made according to the modular approach to meet the production needs in the sector of padded quilts in sectors. An ALAN BEDDIN A is used where high production capacities are required, this can be configured with more pre-weighing modules (from 3 to 12) depending on the hourly production required. The same approach with the injection units on one or two automatic tables let the machine to fill in a short time. ALAN BEDDING A minimizes the use of staff and reduces the waste of raw materials. The system can treat all types of filling materials, from down-feathers to various types of synthetic fibers as long as they are short.

ALAN BEDDING A is the maximum expression of filling machine for the production of quilts, as well as its fulcrum in the production of automatic lines. Customers can obtain performance at the highest level thanks to the complete integration of ALAN BEDDING A with other Borsoi’s machines. Organized in a single production line, according to the “From Bale to Box” philosophy, these machines require few operators and consistently provide high performance.

ALAN BEDDING A is that it is more suited to the needs of the customer and that raises its production to unmatched levels.

Quilt shell automatic warehousing

Quilt shell automatic warehouse is the best option to manage and organize stocks of covers. Integrated with software ERP of the company and with control of Borsoi production line, it optimize the production process despite the high number of different models and sizes of quilts customer has to produce. With automatic warehouse is possible reduce the number of each lot and obtain the multi-mix production which optimize the order‘s trend. Lean production oriented, it is the optimum for production with extreme variety of products or with “pull production” strategy.

Copyright 2022 Borsoi Srl - P.iva 04694270267