FILLING MATERIAL PROCESS

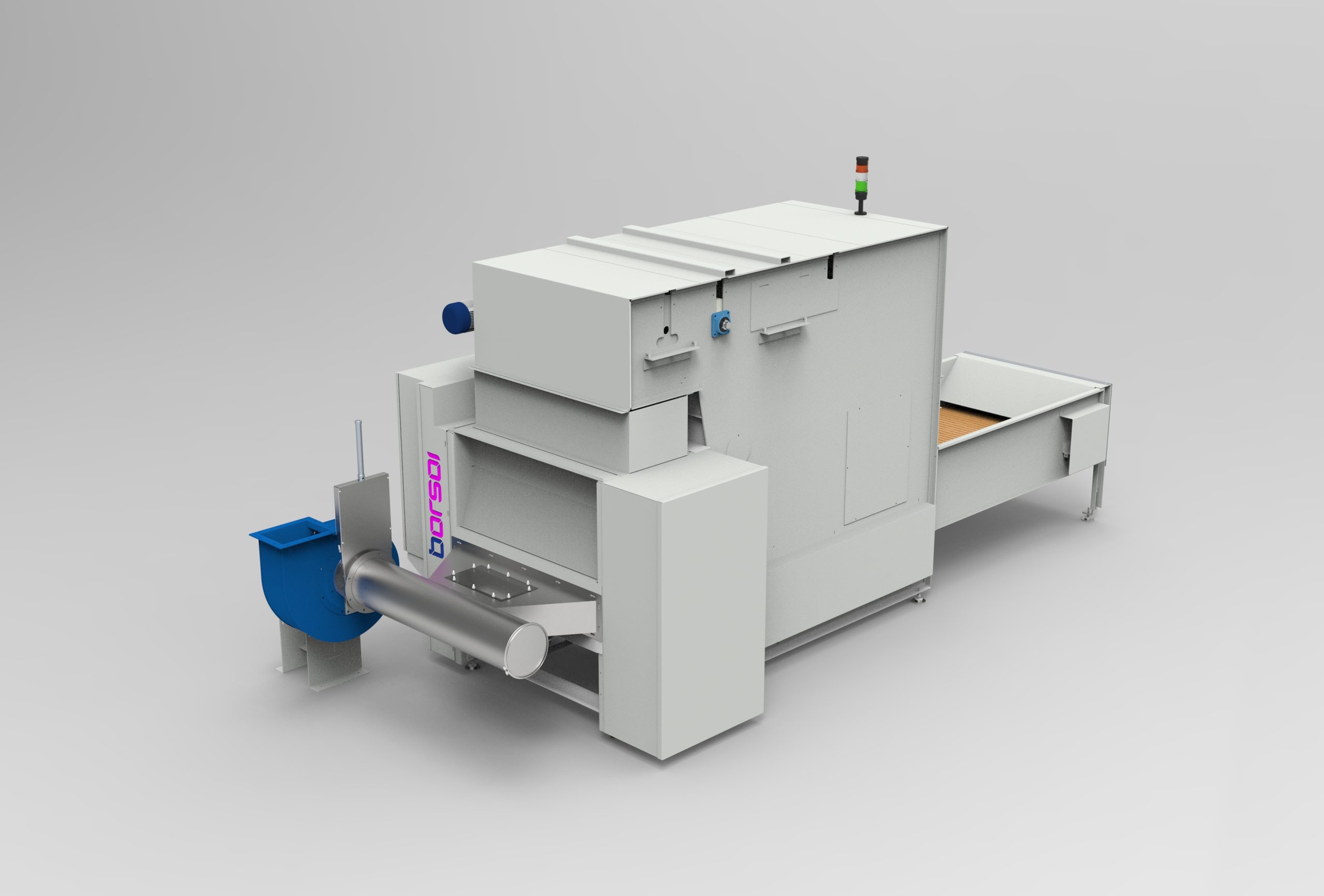

Open Bale and fine fiber opener machine

The open bale and fine fiber opening machine is a integrated solution with the task to open the bale and immediately works as fine fiber opener machine. Three size are available according the throughput and many optional: from the possibility to stock above roller table up to 6 bale which move by gravity to inlet of machine, to secondary blowing systems for filling padded products under operator control for test or pre series samples. The opener drum can be optimized according the length and the kind of the fiber customer needs to process. The ALAN PROLOFT is equipped with an air conveying systems to feeds the open fiber to the rest of the plant.

Fiber Ball system

The fiber ball system performs the process of forming the fiber ball starting from open fiber. The machine is positioned between the fiber opening process and the downstream production processes, such as filling machines. The aggregation effect can be adjusted by making the sphere more or less tight, allowing to modify its final mechanical properties such as softness and lofty. A good fiber ball remains soft and lofty over time without opening. The ALAN fiber ball consists of a truncated cone module through which the previously opened fiber is passed. Each module produces 250 Kg / h of fiber ball (experiences based on 7D HCS 32 mm). It is possible to connect multiple modules in series to achieve the required production, an air transport system conveys the fiber to be processed between one module and another. The ALAN FIBER BALL requires a minimum footprint and can be easily integrated into the “From bale to box” production lines.

Wadding recycling unit

The wadding-recycling unit is composed of a dedicated grinder with special features who let it shred, reduce and grind rag, scrapes of textile, fiber, or other kind of textile product who can be recycled as fiber. Metal detectors are available as optional, to prevent contamination and damage to equipment. The installation is completed with the presence of conveyor belt and air conveyor system.

Feather bale opening

ALAN FBB is a feather bale/Bag opener machine. It’s composed of a crane system for lifting feather bag/bale and discharge it onto a transportation belt. Feather is moved to a rotating shaft with rods and a ventilator, those devices are opening the filling product and convey it to a filling machine storage box, or an additional storage silo, or a mixer. The presence of perimeter painted carbon steel walls and the air conveyor systems, prevent material leakage and contamination of the surrounding area.

Foam granulator

Foam granulator shred and grind scraps of foam to small size grinded foam suitable to be use as filler for padding products. Dust collectors and metal doctors are available to prevent contamination, damage to equipment and contamination of the surrounding area. The installation is completed with the presence of conveyor belt and air conveyor system.

Alan Silo

ALAN SILO is a flexible system to manage the handling, storage of feathers, down feathers and/or synthetic fibres before these are used in a filling system. The ALAN SILO machine is an additional storage box, is composed of a metal tank with a rotor shaft fitted with blades as well as a contrasting wooden cabin. The material is conveyed to the internal tank, by means of a suction unit (optional) or external conveying system.

Alan Mixer

ALAN MIXER is a flexible system to manage the handling, storage and mixing of feathers, down feathers and/or synthetic fibres before these are used in a filling system. The ALAN MIXER machine, used as an additional storage box, is composed of a metal tank with a rotor shaft fitted with blades as well as a contrasting wooden cabin. The material is conveyed from the external load tank to the internal tank, by means of a suction unit incorporated into the machine structure. In case it is used also as a mixing system, ALAN MIXER is fitted with a weighting system to control the amount of material to be mixed: the weighting system is available in various configurations in order to fulfil the varying demands of the existing production systems.

Copyright 2022 Borsoi Srl - P.iva 04694270267