ROLLED CARDED FIBER (garnetted) PILLOWS

Fibre bale opening

Borsoi bale opener machine supports operator into the hard work of opening bales of polyester fiber. The machine is equipped with wide inlet and the capacity to process up to 1500 kg/h of material (based on fiber no longer than 32 mm). The machine ALAN FBO is easy to use and to maintain, designed according modular solution. That machine can be plugged with up to 3 modules of open fiber machine, in order to obtain compact solution, minimum footprint and avoid intermediate transport between machines, as foresee in classical application.

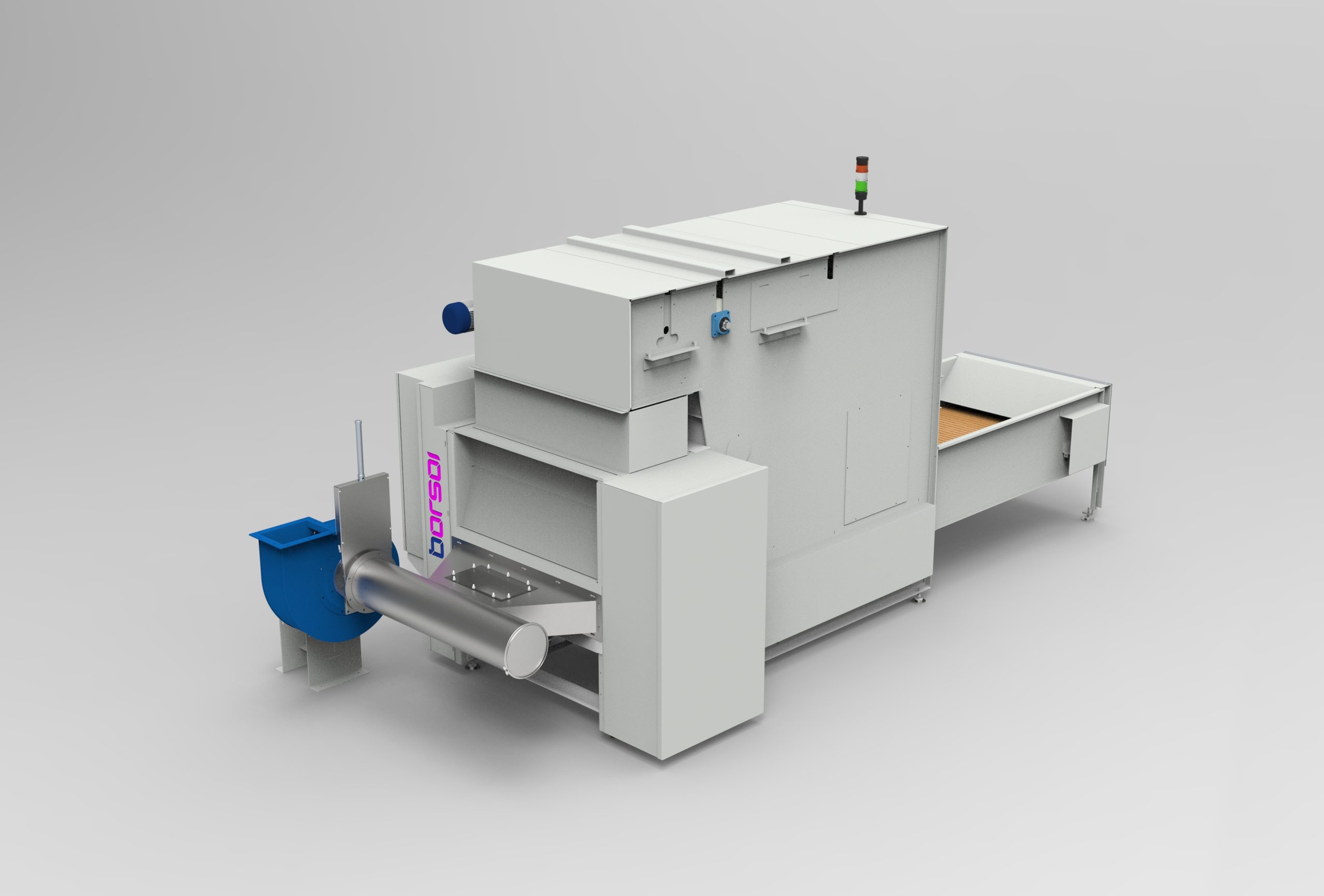

Fibre fine opener

The fibre fine opener machine ALAN FFO, process up to 500 kg/h in continuous (based on polyester fiber 7D HCS 32 mm). It can be integrate into automatic production lines “From bale to box”. The raw material as bale move into the bale opener, than pass to the fine opener module, than to the rest of plant. The final product can be used for filling quilts, garments, sleep covers, mattress etc. The machine is not just set inside the production line but is connected and integrated both mechanically and via software. The software supervisor “Bale to Box”, manage the line as a whole, as a single unit, suppling to personnel all the information necessary to manage in the right way and according the best practice. That’s the only way to obtain the maximum of the line. The benefit of the multi-needing coupled with the automation of Borsoi.

Fibre blending machine

Fibre blending equipment is a cluster of opening machine, one for each component of the blend, linked together with a weighting system above conveyor belt. Weighted material is than conveyed to fiber fine opener machine where the blend of open fiber is finally obtained. Borsoi blending machine are equipped with plc and touch screen for agile interface with operators, remote internet access for prompt service support is also set as standard. Fiber blend machine can deal up to 2500 kg/h of blend fiber and up to 6 components of the blend. That’s kind of equipment can be integrated into a line “From bale to Box” with all benefit associated. The software supervisor “Bale to Box”, manage the line as a whole, as a single unit, suppling to personnel all the information necessary to manage in the right way and according the best practice.

Wadding recycling unit

The wadding-recycling unit is composed of a dedicated grinder with special features who let it shred, reduce and grind rag, scrapes of textile, fiber, or other kind of textile product who can be recycled as fiber. Metal detectors are available as optional, to prevent contamination and damage to equipment. The installation is completed with the presence of conveyor belt and air conveyor system.

Alan Silo

ALAN SILO is a flexible system to manage the handling, storage of feathers, down feathers and/or synthetic fibres before these are used in a filling system. The ALAN SILO machine is an additional storage box, is composed of a metal tank with a rotor shaft fitted with blades as well as a contrasting wooden cabin. The material is conveyed to the internal tank, by means of a suction unit (optional) or external conveying system.

Alan Mixer

ALAN MIXER is a flexible system to manage the handling, storage and mixing of feathers, down feathers and/or synthetic fibres before these are used in a filling system. The ALAN MIXER machine, used as an additional storage box, is composed of a metal tank with a rotor shaft fitted with blades as well as a contrasting wooden cabin. The material is conveyed from the external load tank to the internal tank, by means of a suction unit incorporated into the machine structure. In case it is used also as a mixing system, ALAN MIXER is fitted with a weighting system to control the amount of material to be mixed: the weighting system is available in various configurations in order to fulfil the varying demands of the existing production systems.

Copyright 2022 Borsoi Srl - P.iva 04694270267