CLOSING AND LEVELLING

Manual and automatic lockstitch closing

The automatic closing machines are expressly realized for the closing of the cushions through automatisms. These composed by one or two sewing heads connected to a frame with motorized axes. The movements necessary for the sewing operations are controlled by a PLC and a touch screen with intuitive graphics, making it easier for operators to use.

In the semi-automatic version, the operator inserts the cushion to the gripping elements and initiates the start through a two-hand command.

Both versions can be equipped with two sewing heads on a quick-change rotary table. This method is very useful into automatic lines with Lockstitch closure. In that case one sewing head is working while the second one is in maintenance or spool changes, with no idle time.

In the automatic version, the insertion takes place through the use of an anthropomorphic robot.

Further configurations are available to be combined with the filling machines according to their hourly production.

Alan Flex Sew AO-1

ALAN FLEX SEW AO-1 is equipped with one overlock sewing head and got all the features to fit into one automatic production line “From Bale to Box” . The machine can receive the cushion from filling machine by an arm elbow robot who pick up the filled cushion and set it to the clumps of ALAN FELX SEW AO-1, than the machine works automatically. The performance and reliability of overlock sewing are improved with the productivity and constancy of automation. If required the machine can be rapidly converted in semiautomatic mode, that’s can happen in case of special out of specs cushion.

Alan Flex Sew AO-2

ALAN FLEX SEW AO-2 is equipped with two overlock sewing head above rotary table and got all the features to fit into one automatic production line “From Bale to Box” . The machine can receive the cushion from filling machine by an arm elbow robot who pick up the filled cushion and set it to the clumps of ALAN FELX SEW AO-2, than the machine works automatically. The performance and reliability of overlock sewing are improved with the productivity and constancy of automation. If required the machine can be rapidly converted in semiautomatic mode, that’s can happen in case of special out of specs cushion.

Alan Flex Sew MO-1

ALAN FLEX SEW MO-1 is equipped with one overlock sewing head and is designed to be integrated in Semi-automatic mode to one automatic production line “From Bale to Box”. The machine receives the cushion from filling machine from an operator who pick up the filled cushion and set it to the clumps of ALAN FELX SEW MO-1, than the machine works automatically. The performance and reliability of overlock sewing are improved with the flexibility of operator. According to its special design, the ALAN FLEX SEW MO-1 model is also suitable for other types of sewing processes in textile production by allocating specialized personnel to more demanding jobs.

ALAN FLEX SEW AL-1

ALAN FLEX SEW AL-1 is equipped with one lockstitch sewing head and got all the features to be set into one automatic production line “From Bale to Box” . The machine can receive the cushion from filling machine true an arm elbow robot who pick up the filled cushion and set it to the clumps of ALAN FELX SEW AL-1, than the machine works automatically. The performance and reliability of lockstitch sewing are improved with the productivity and constancy of automation.

ALAN FLEX SEW AL-2

ALAN FLEX SEW AL-2 is equipped with two lockstitch sewing head above rotary table and got all the features to be set into one automatic production line “From Bale to Box” . The machine can receive the cushion from filling machine true an arm elbow robot who pick up the filled cushion and set it to the clumps of ALAN FELX SEW AL-2, than the machine works automatically. The machine with two lockstitch sewing head is the right choice for high production ratio. In that case one closing head is working while the second one is in maintenance or spool changes, with no idle time. The performance and reliability of lockstitch sewing are improved with the productivity and constancy of automation.

ALAN FLEX SEW ML-1

ALAN FLEX SEW ML-1 is equipped with one lockstitch sewing head and is designed to be integrated in Semi-automatic mode to production line “From Bale to Box” . The machine receives the cushion from filling machine true an operator who pick up the filled cushion and set it to the clumps of ALAN FELX SEW ML-1, than the machine works automatically. The performance of lockstitch sewing are improved with the flexibility of operator. According to its special design, the ALAN FLEX SEW ML-1 model is also suitable for other types of sewing processes in textile production by allocating specialized personnel to more demanding jobs.

ALAN FLEX SEW AU-1

ALAN FLEX SEW AU-1 is equipped with one ultrasonic welding head to close TNT covers and got all the features to be set into one automatic production line “From Bale to Box”. The machine can receive the cushion from filling machine true an arm elbow robot who pick up the filled cushion and set it to the clumps of ALAN FELX SEW AU-1, than the machine works automatically. The performance and high reliability of ultrasonic closing are improved with the productivity and constancy of automation.

ALAN FLEX SEW MU-1

ALAN FLEX SEW MU-1 is equipped with one ultrasonic welding head and is designed to be integrated in Semi-automatic mode to production line “From Bale to Box” . The machine receives the cushion from filling machine true an operator who pick up the filled cushion and set it to the clumps of ALAN FELX SEW MU-1, than the machine works automatically. The performance and reliability of ultrasonic welding are improved with the flexibility of operator. According to its special design, the ALAN FLEX SEW ML-1 model is also suitable for other types of sewing processes in textile production.

Cushion leveling

The ALAN FLEX LEVEL S is the one dedicated to level cushion, cushions and small padded items. The machine is composed of a frame with belt where cushion pass under one vertical axes with customized tool. After the leveling axe, two counter-rotating brush rollers with one dust extractor hood clean the cushion and let it out the machine. One aspiration fun with filter ad dust collectors are available as optional. All leveling parameter are adjustable such as the rotation speed or brushes.

The leveling tools is easily replaceable. Operator can easily set up the machine by the use of a touch screen. Each kind of cushion are processed in customized way.

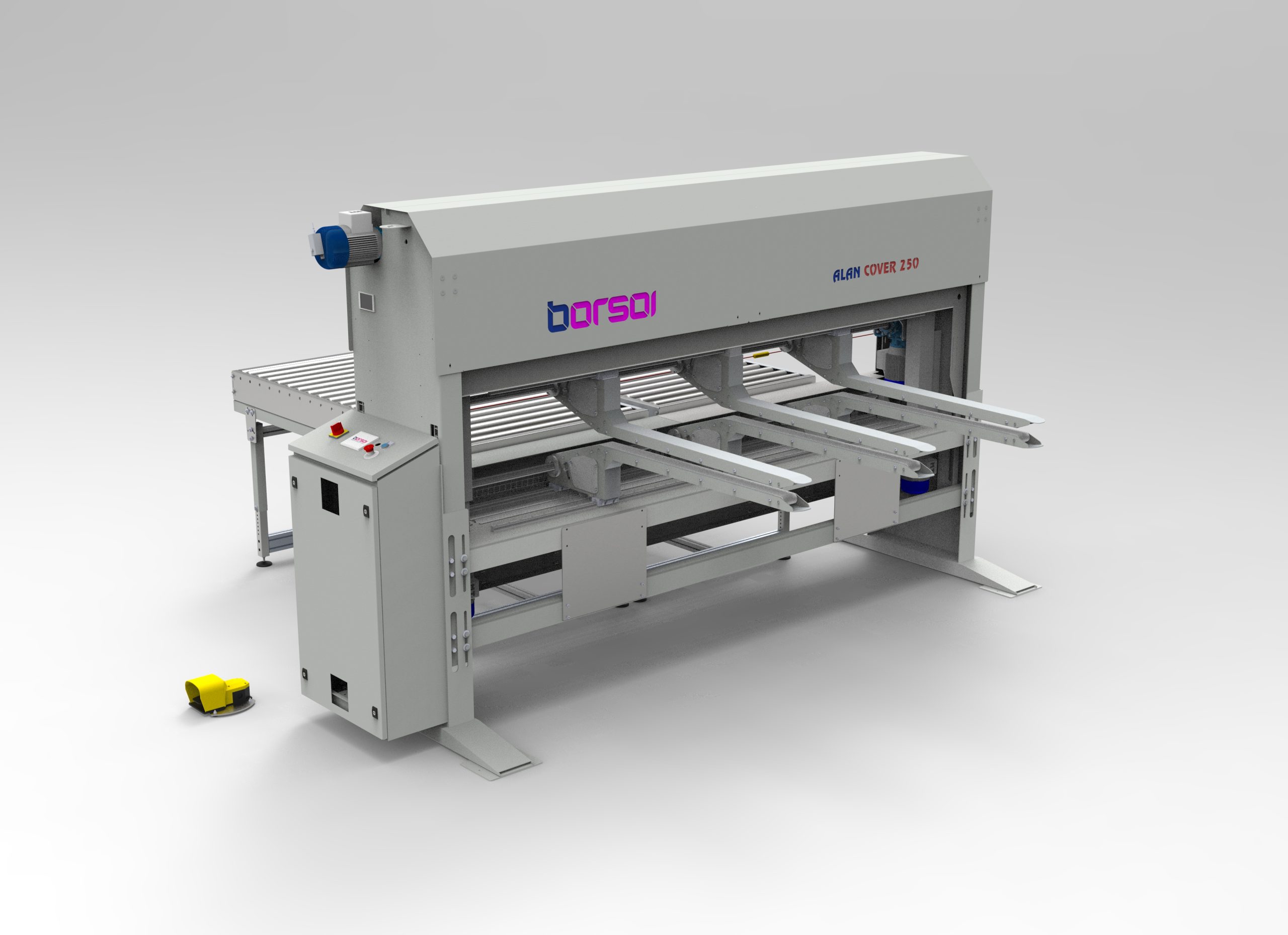

Alan Cover

The ALAN COVER series of machines facilitate the operation of inserting the covers into the cushions. Although it seems like a trivial process, the physical effort in carrying out the machining by an operator is very intense and time-consuming. The Cover series favors the application of covers on cushions, reducing efforts and execution time.

The ALAN COVER 130

The ALAN COVER 130 is a machine that allows one operator to insert a cover to the cushions for sofas, armchairs and other upholstery applications. The machine is equipped with motorized axles, forks equipped with belts and a solid frame, which allows an operator to insert a cover to the cushions for sofas, armchairs and other upholstery applications. A minute PLC control interface on a touch screen facilitates the operator’s interaction with the machine. The ALAN COVER 130 grabs and compresses the cushion, and then slides it inside the cover with the help of the operator. All the physical effort of the operation is carried out by the machine, to the operator remains the handling of the external cover. This machine is particularly effective for processing sofa cushions and bulky items. Like all Borsoi machines, the ALAN COVER 130 is designed to be integrated, in semi-automatic mode, into a “From Bale to Box” production line.

The ALAN COVER 250

The ALAN COVER 250 is a machine that allows one operator to insert a cover to the cushions for sofas, armchairs and other upholstery applications. The machine is equipped with motorized axles, forks equipped with belts and a solid frame, which allows an operator to insert a cover to the cushions for sofas, armchairs and other upholstery applications. A minute PLC control interface on a touch screen facilitates the operator’s interaction with the machine. The ALAN COVER 250 grabs and compresses the cushion, and then slides it inside the cover with the help of the operator. All the physical effort of the operation is carried out by the machine, to the operator remains the handling of the external cover. This machine is particularly effective for processing sofa cushions and bulky items. Like all Borsoi machines, the ALAN COVER 250 is designed to be integrated, in semi-automatic mode, into a “From Bale to Box” production line.

The ALAN COVER TX

The ALAN COVER TX is a machine that allows an operator to insert a cover to the cushions for sofas, armchairs and other small and medium-sized upholstery applications. The machine is equipped with motorized axes, a series of jaws / tools, a conveyor belt, a pusher axis and a solid frame. A minute PLC control interface on a touch screen facilitates the operator’s interaction with the machine. The ALAN COVER TX grabs and compresses the cushion using the tools, and then slides it inside the cover with the help of the operator and the forcing axis. All the physical effort of the operation is carried out by the machine, to the operator remains the handling of the external cover. This machine is particularly effective for processing sofa cushions and bulky items. Like all Borsoi machines, the ALAN COVER TX is designed to be integrated, in semi-automatic mode, into a “From Bale to Box” production line both upstream and downstream.

Metal detection

The metal detector is used to avoid the broken needle or small metal parts will be delivered inside the cushions. One of the main topics in the quality control of cushion manufacturing is the prevention of metal contamination. Such a piece of equipment is usually placed on a conveyor belt where the cushions move along the manufacturing plant. The metal detector is coupled with a automatic scrap flap to maintain high line performance and at the same time avoid human intervention.

UV processing

UV PROCESSING machine satisfy the needs of customer to reduce and stabilize the bacteria threshold into cushion produced. UV lamps are used inside enclosure where cushion are moved into with a belt conveyor. Slide doors close the UV chamber during process. Exposition time change according filling material and textile employed to produce cushion.

Copyright 2022 Borsoi Srl - P.iva 04694270267