NEWS

The Borsoi preview at ITMA 2019 - From bale to Box

At the ITMA 2019 Borsoi will present an absolute preview for the textile sector: the first fully automated pillow production line, from the preparation of the filling material to the final packaging, a new line concept called “from Bale to Box” as an evolution of what was proposed at Heimtextil 2019.

Discover the technical details in the article and ask to reserve an appointment to receive all the information during the live demonstration at ITMA 2019 by contacting us at marco@borsoi.eu.

“from Bale to Box” completes development

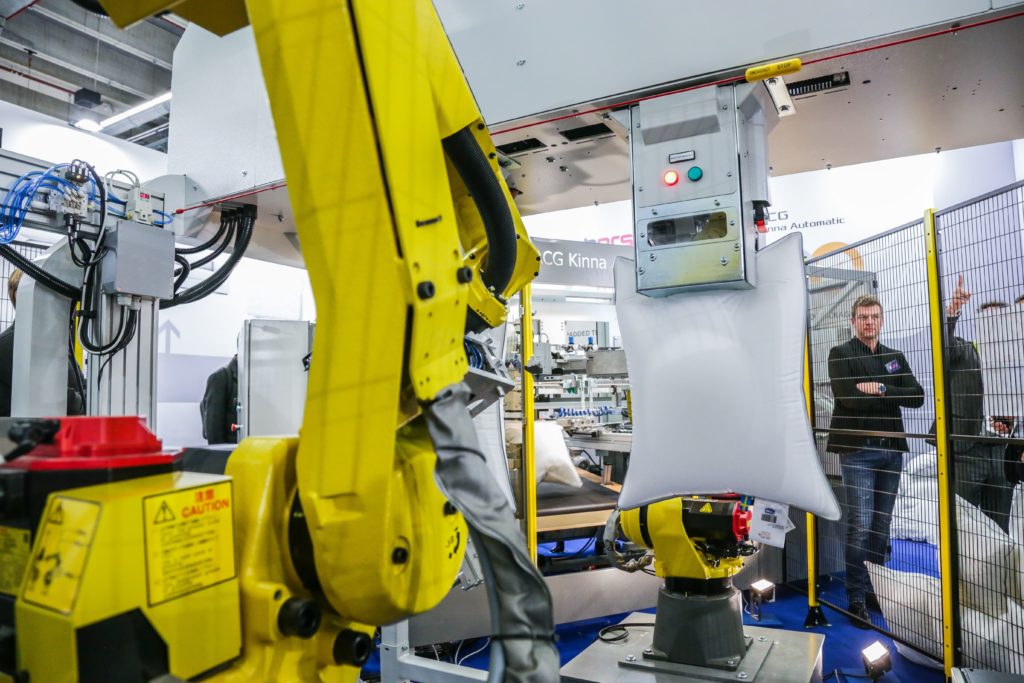

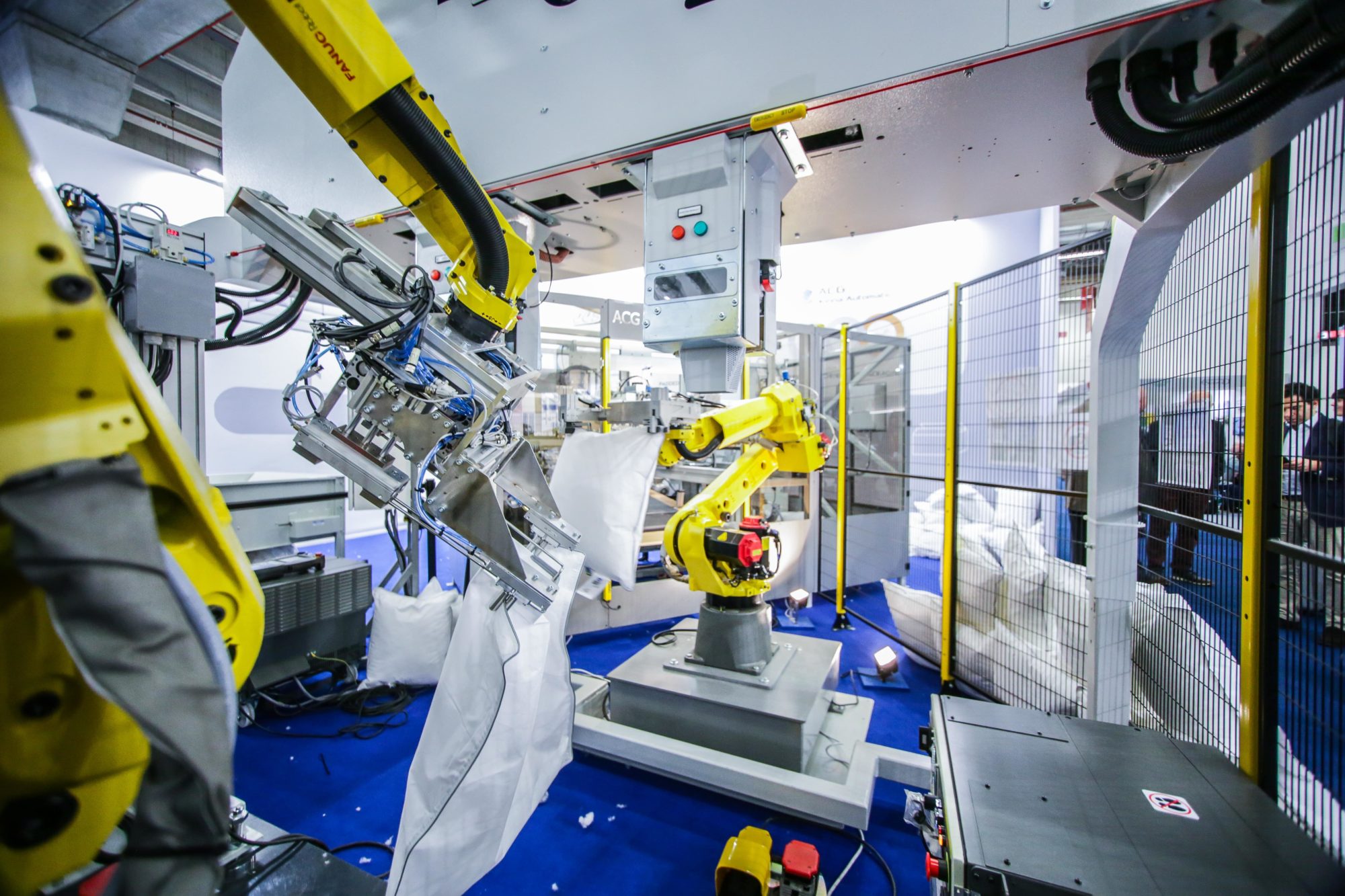

The new production line “from Bale to Box” is the result of the collaboration of three international partners. In addition to Borsoi, a company that has been active in the textile sector since 1985, the project includes the participation of ACG Kinna Automatic, a Swedish company specialised in automation for textiles that has been active since 1977, and CCS – Card Clothing and Services, a leading US company in the design of production lines for carding.

ITMA 2019 is the venue to receive the technical details directly by Borsoi, with the focus on the last production phases: packaging and carton box forming for logistics.

Let’s see in detail in the next paragraph what other phases of the “from Bale to Box” system have been added.

All phases of the complete cycle “from Bale to Box”.

Fibre opening phase: the system that prepares the polyester fibre for the subsequent processing phases.

Pre-weighing and automated filling phase with robotic cell composed of two robotic arms. The first robot peels off the empty shell from a pile and directs the insertion on the injection unit (filling). The second robot takes the filled pillow and takes it to the next stage of pillow closing.

Pillow closing: the automatic sewing system, which receives the filled pillow open.

Levelling system: makes the internal material homogeneous with controlled stresses.

New packaging system: forms the wrapper from a roll of film, inserts the cushion and closes it.

New carton box forming system: forms the packaging boxes.

New stacking and closing system: creates the stack of pillows previously packed and inserts it into the carton box.

– End of the line.

“from Bale to Box” – the project partnership

The new production line “from Bale to Box” is the result of the collaboration of three international partners. In addition to Borsoi, a company that has been active in the textile sector since 1985, the project includes the participation of ACG Kinna Automatic, a Swedish company specialised in automation for textiles that has been active since 1977, and CCS – Card Clothing and Services, a leading US company in the design of production lines for carding.

The partnership boasts the primacy of the creation of new generation production lines for the textile sector, applying the philosophy of Open Innovation to its projects, i.e. the ability to design and develop innovative solutions based on the principles of Industry 4.0 for always different application fields.

“FROM BALE TO BOX” – THE PROJECT

The project boasts the primacy of the creation of new generation production lines for the textile sector, applying the philosophy of Open Innovation to its projects, i.e. the ability to design and develop innovative solutions based on the principles of Industry 4.0 for always different application fields.

Copyright 2022 Borsoi Srl - P.iva 04694270267