NEWS

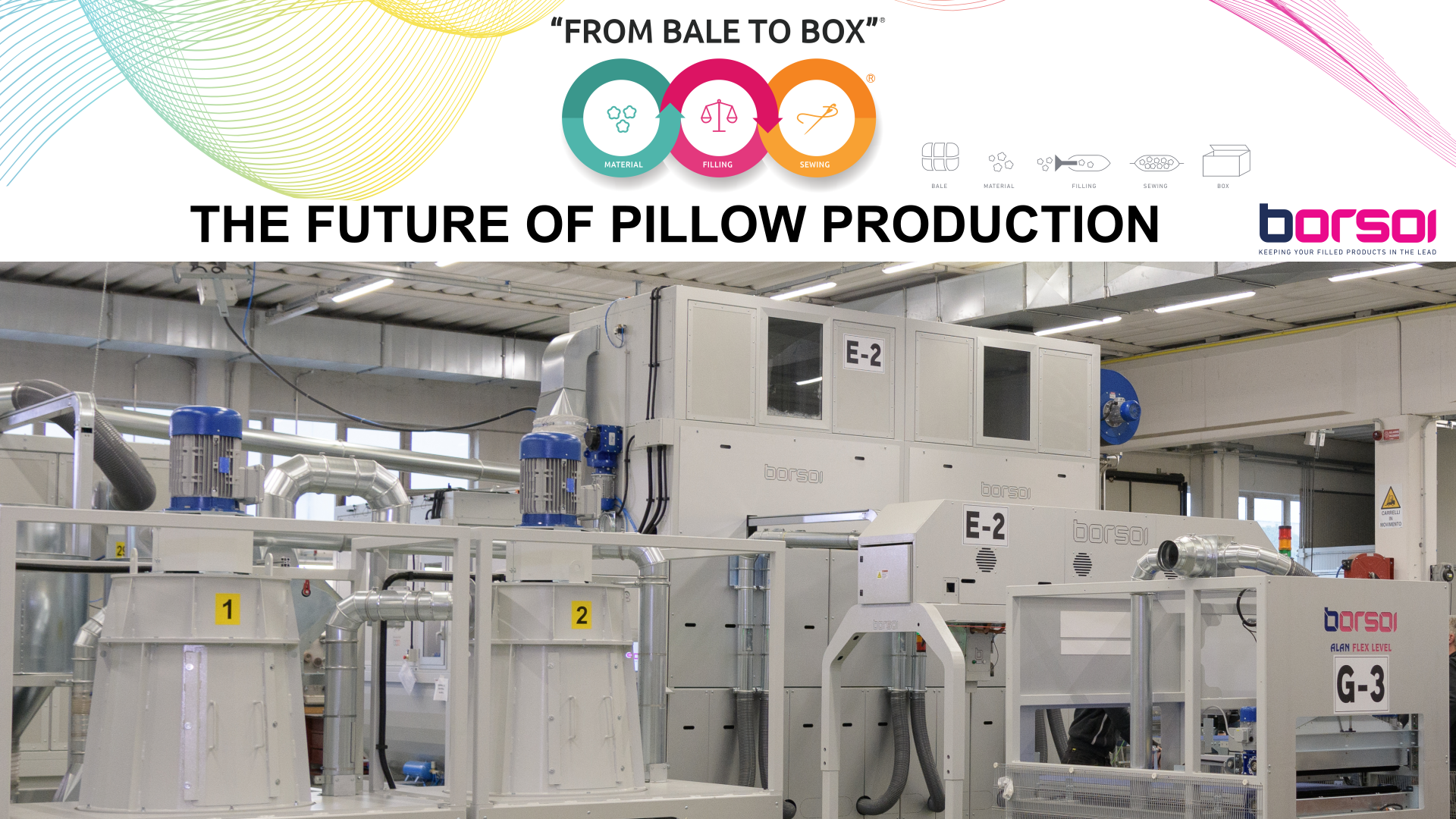

The Future of Pillow Production: the "From Bale to Box" approach by Borsoi

In the evolving world of manufacturing, staying ahead requires constant innovation. This is especially true in the textile industry, where efficiency, quality and sustainability are critical. Borsoi is developing advanced pillow production machines. Our unique approach, named “From Bale to Box,” is transforming pillow manufacturing. This article explores the numerous benefits of using pillow production solutions from Borsoi and explains the “From Bale to Box” methodology.

Precision and Consistency in Pillow Manufacturing

One of the primary advantages of pillow production machines realized from Borsoi, is their ability to manufacture pillows with precision and consistency to ensure that every pillow meets specific standards for comfort and support. Traditional pillow production methods often result in pour fill accuracy and distribution, leading to lumps and poor quality of the product.

The Borsoi machines fix this issue by using well designed and innovative pre-weighing, filling and leveling mechanisms that ensure consistency and distribution of materials such as down, feathers, synthetic fibers or blends. This translates into a more comfortable and supportive pillow.

Customization Capabilities

Borsoi offer manufacturers the flexibility to customize pillows production machines according to diverse customer needs and specifications. Whether it’s creating pillows with varying filling materials, different size of shells, or features like zip or decorative piping, the “From Bale to Box” pillow production lines enable the production of a wide range of pillow types, all tailored to meet specific consumer demands.

Efficient Automated Processes

Designed with automation in mind, the solutions from Borsoi can minimize manual intervention throughout the production cycle. From the initial processing of raw materials to the final packaging of finished pillows, each step can be automated. The “From Bale to Box” approach allows seamless integration of all production stages, from the initial processing of raw materials (bales) to the final packaging of finished pillows (box), in an end-to-end production flow ensuring a consistently high-quality product and efficient process. In that way we eliminates bottlenecks but also reduces the likelihood of human error.

Those integrations are equipped with real-time monitoring systems that track various parameters throughout the production process. This allows manufacturers to identify and address issues promptly with the support of the Borsoi Service team, ensuring optimal performance and minimizing downtime.

High Output Capacity

The advanced technology employed by Borsoi allows for a high output capacity, enabling manufacturers to produce large quantities of pillows in a short period. This is particularly beneficial for companies looking to meet high demand or expand their market reach. The increased efficiency also translates into cost savings, as manufacturers can produce more pillows with fewer resources.

Conclusion

In the evolving landscape of pillow production Borsoi leads the innovative “From Bale to Box” approach as a game-changer. By leveraging advanced technology, automation and modern production Borsoi’s pillow production machines offer unparalleled benefits in terms of efficiency, sustainability and cost savings.

Manufacturers adopting our solutions can expect to produce high-quality pillows that meet the diverse needs of today’s consumers while also achieving significant cost and environmental benefits. The “From Bale to Box” approach not only streamlines the production process but also empowers manufacturers to innovate and stay ahead of market trends.

Copyright 2022 Borsoi Srl - P.iva 04694270267